ENG_116357.XML

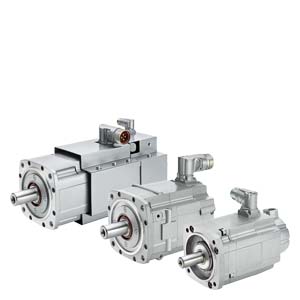

Built-in holding brakes for SIMOTICS S-1FT7/S-1FK7 motors

Many drives need a holding brake with an EMERGENCY-STOP function for safety reasons or to meet process requirements.

The permanent magnet single-surface brakes used on the SIMOTICS S-1FT7/S-1FK7 motors function according to the closed-circuit principle. The magnetic field of the permanent-magnet pulls on the brake armature disk, i.e. in a condition of zero current, the brake is closed and the motor shaft thereby stopped. When the rated voltage of 24 V DC ± 10 % is applied to the brake, current flows through the coil and produces a counter-field that cancels the pull of the permanent magnet, causing the brake to release.

In the event of an EMERGENCY STOP or power outage, approximately 2000 braking operations can be performed at the maximum switched energy without causing excessive wear on the holding brake.

Condition: Maximum external moment of inertia = moment of inertia of motor and nmax (type-specific).

The holding brake is not an operational or safety brake.

To avoid switching overvoltages and any related impact on the system environment,a varistor must be externally connected to brake connecting cables. The connection is established using a power connector or terminal box.

When connected to the SINAMICS S120 drive system, this overvoltage protection is already included.