ENG_432834.XML

P_D213_XX_00045

Flexibility for successful crane concepts

As part of the SINAMICS converter family, the SINAMICS S120 drive is a modular system for high-performance applications in crane construction. SINAMICS S120 offers high-performance single-axis and multi-axis drives for a very broad range of crane applications. By virtue of its scalability and flexibility, SINAMICS S120 is the ideal system for satisfying the ever increasing demand for more axes and better performance. SINAMICS S120 supports flexible crane concepts and speedy implementation of customized drive solutions.

The response to ever increasing demands

Modern cranes must be built at ever lower cost, but deliver ever greater productivity. The SINAMICS S120 drive concept meets both these challenges! It is easy to configure and thus helps to reduce project completion times. Its excellent dynamic response and accuracy permit higher cycle rates for maximum productivity.

Application areas in crane construction

SINAMICS S120 enhances the performance of cranes, in both industrial and harbor crane systems:

- Container cranes

- Grab cranes

- Stacking cranes

- Ladle cranes

- Bridge cranes

- Goliath cranes

Modularity for crane construction

SINAMICS S120 is designed to allow free combination of power and control performance. Multi-axis drives with higher-level motion control can be implemented with the SINAMICS S120 modular system as easily as single-drive solutions.

Greater flexibility with central control intelligence

On the SINAMICS S120, the drive intelligence is combined with closed-loop control functions into Control Units.

These units are capable of controlling drives in Vector, Servo and V/f modes. They also perform the speed and torque control functions plus other intelligent drive functions for all axes on the drive. Vector control is used in crane applications.

SINAMICS S120 – functions for better efficiency

- Basic functions: Speed control, torque control, positioning functions

- Intelligent starting functions for independent restart after power supply interruption

- BICO technology with interconnection of drive-related I/Os for easy adaptation of the drive system to its operating environment

- Integrated safety functions for rational implementation of safety concepts

- Regulated infeed/regenerative feedback functions for preventing undesirable reactions on the supply, allowing recovery of braking energy and ensuring greater stability against line fluctuations.

DRIVE-CLiQ – the digital interface between all components

All SINAMICS S120 components, including the motors and encoders, are interconnected by a shared serial interface called DRIVE‑CLiQ. The standardized cables and connectors reduce the variety of different parts and cut storage costs. Converter boards (Sensor Modules) for converting standard encoder signals to DRIVE-CLiQ are available for third‑party motors or retrofit applications.

Swift and automatic: The electronic rating plate

An important digital linkage element of the SINAMICS S120 drive system are the electronic rating plates integrated in every component. They allow all drive components to be detected automatically via a DRIVE-CLiQ link. As a result, data do not need to be entered manually during commissioning or component replacement – helping to ensure that drives are commissioned successfully! The electronic rating plates of the motors contain, for example, the parameters of the electrical equivalent circuit diagram and the characteristic data of the built‑in motor encoder in addition to information such as order and identification numbers.

Modular design ensures flexibility and scalability

DC/AC units (Motor Modules) – available in compact booksize, booksize and chassis formats – are characterized by their modular design. All the drive intelligence is organized into Control Units. The Control Units perform all the closed-loop control functions for the drive line-up. They also handle all other drive functions such as the interconnection of drive-related I/Os, positioning functions, and feature PROFIBUS DP or PROFINET as the central interface for linking to higher-level automation systems.

Line Modules function as the central energy supply to the voltage‑source DC link. Line Modules are optionally available with regulated infeed/regenerative feedback to provide a constant DC link voltage and high level of supply compatibility. Motor Modules supply the motors with energy from the DC link.

Configurable control cabinets based on Motor Modules and Line Modules in chassis format can be ordered in Cabinet Module format.

On AC/AC units, the infeed and motor power supply functions are combined in one device, the Power Module – available in blocksize and chassis formats. For single-axis applications, drive control functions are performed by a special Control Unit (CU310-2) mounted on the Power Module and for multi-axis applications, by a Control Unit (e.g. CU320-2) connected by a DRIVE-CLiQ link. In this case, a Control Unit Adapter is mounted on the Power Module in place of the Control Unit.

P_D211_XX_00411

SINAMICS S120 blocksize, booksize compact, booksize, chassis and Cabinet Module formats

All formats can be combined as required

The different SINAMICS S120 formats can be combined freely thanks to their DRIVE-CLiQ interfaces, e.g. Line Modules in chassis format can be freely combined with Motor Modules in booksize format for multi-axis applications with high total output.

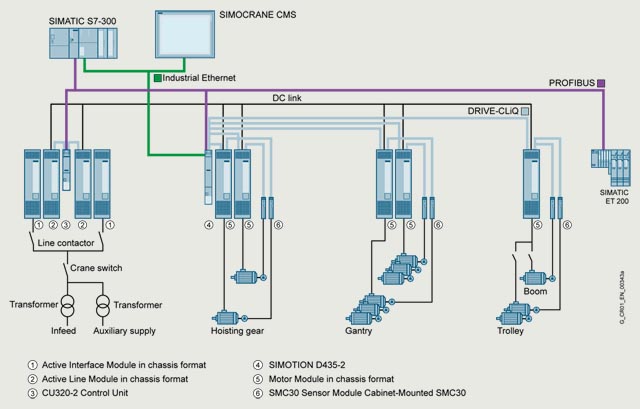

G_CR01_XX_00343

Container crane topology with chassis format

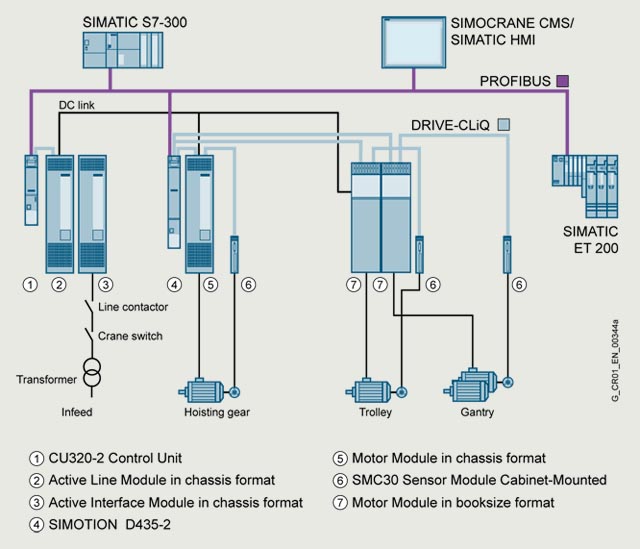

G_CR01_XX_00344

Bridge crane topology with chassis and booksize formats

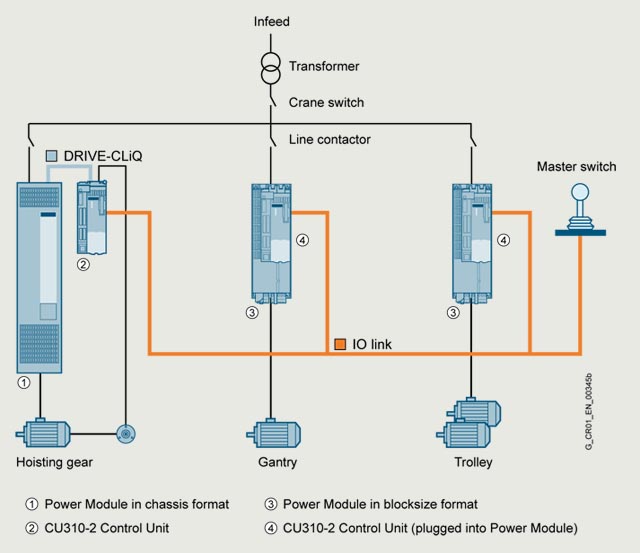

G_CR01_XX_00345

Bridge crane topology with Power Modules in chassis and blocksize formats