Overview

ENG_680401.XML

P_PCS7_XX_00891

ET 200SP HA redundant standard SUB-D Ex

Compact design, flexible connection possibilities and high system availability with redundant PROFINET connections: the SIMATIC ET 200SP HA distributed I/O system is perfectly suited to the requirements of the process industry. The new design allows up to 56 I/O modules per station. An impressively high concentration of up to 32 channels on a module that is only 22.5 mm wide allows for maximum economy in the control cabinet.

Redundant PROFINET connections allow the connection of high-availability controllers via two independent networks, with a choice of copper or fiber-optic cables. The system can be scaled and extended in small steps using a variety of available modules, for example with digital and analog I/Os as well as NAMUR, HART, and other protocols. All 24 V standard signals are connected via an identical terminal block type, which allows a high degree of standardization for the control cabinets.

SIMATIC ET 200SP HA is designed for use in the control cabinet as well as for hazardous areas up to Ex zone 2. The extended temperature range from -40 to +70 °C and the conformal coating of all components allow direct installation in the field.

You also benefit in engineering from seamless integration in SIMATIC PCS neo. The SIMATIC ET 200SP HA in combination with the Advanced Process Library also offers flexible and simple online parameter assignment.

Benefits

ENG_680415.XML

Highlights at a glance

- Availability

- Redundancy at the PROFINET interface (S2 or R1)

- Hot swapping during runtime

- Station expansion possible during runtime

- Easy to use

- Compact modules with permanent wiring

- One terminal block for all 24 V standard signals

- Tool-free connection system with push-in terminals

- Compact design

- Compact with up to 56 I/O modules per station

- High concentration of up to 32 channels on a module that is only 22.5 mm wide

- System-integrated power bus

- Seamless integration in SIMATIC PCS neo

- PROFINET IO communication standard

Design

ENG_680400.XML

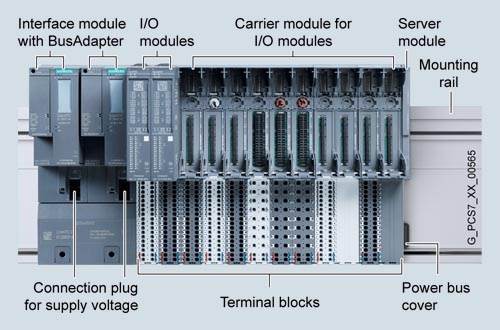

G_PCS7_XX_00565

ET 200SP HA for SIMATIC PCS neo, structure

Easy handling and high availability

The SIMATIC ET 200SP HA impresses with its particularly simple installation and assembly. The new terminal layout and push-in technology make tool-free wiring possible. Control cabinet configuration is particularly flexible, as the separation of mechanical and electronic components allows the station to be pre-wired without I/O modules. Empty modules can be inserted in the integrated terminal blocks and easily replaced at any time. Station extension during operation offers additional advantages for plant flexibility and availability.

Main components of the SIMATIC ET 200SP HA distributed I/O system

The SIMATIC ET 200SP HA distributed I/O system consists of the following components:

DIN rail

The DIN rail is required for fitting an ET 200SP HA station in the control cabinet. The IM carrier modules for interface modules, the carrier modules for the I/O modules and the server module are attached to the DIN rail.

IM carrier module for interface modules

Two variants of the IM carrier modules are available:

- IM single carrier module for 1 interface module, for single connection to PROFINET

- IM redundant carrier module for 2 interface modules, for redundant connection to PROFINET

IM 155‑6 PN interface module and BusAdapter

The interface module ensures communication between the ET 200SP HA station and the automation system (controller) via PROFINET. A BusAdapter as a separate component allows a free choice of connection technology:

- BA 2×RJ45: 2 electrical connections for bus cable with standard RJ45 connector

- BA 2×FC: 2 electrical connections for direct connection of FastConnect bus cable

- BA 2×LC: 2 optical ports for fiber-optic cables

- BA 1×LC, 1×RJ45: Mixed BusAdapter 1 optical connection and 1 electrical connection standard RJ45

- BA 1×LC, 1×FC: Mixed BusAdapter 1 optical connection and 1 electrical connection for direct connection of FastConnect bus cable

- BA 2×RJ45 VD: 2 electrical connections for Ethernet communication via 2-, 4- or 8-wire copper cables and distances up to 500 m

Carrier module and terminal blocks for I/O modules

The slots for the I/O modules are created by connecting carrier modules and terminal blocks. The carrier modules provide the electrical and mechanical connections for the individual modules; the terminal blocks contain the process terminals for connecting sensors, actuators and other devices.

Two versions of the carrier modules are available, one with 2 slots and one with 8 slots for I/O modules.

The selection of available terminal blocks determines the following properties:

- Type of load voltage supply

- Formation of potential groups

- Type of required I/O module

- Redundant configuration of I/O modules

I/O modules

Modules with 8, 16 or 32 digital channels (DI, DQ) and with 8 or 16 analog channels (AI, AQ) are available as I/O modules. A relay module (RQ) and a universal digital module DI/DQ are also available.

Slot covers can be attached if IO modules are not to be inserted in slots or slots are to be reserved for later expansion. You can insert a label strip for the planned I/O module on the front of the slot cover.

Server module and power bus cover

The server module and power bus cover complete the configuration of the ET 200SP HA station. The power bus cover protects the power bus contacts.

Function

ENG_680407.XML

Main functions

Compact I/O modules

- Up to 32 channels on a module that is 22.5 mm wide

- Up to 56 modules per station

Perfectly suited for applications in the field

- Installation up to hazardous zone 2

- Extended temperature range: -40 to +70 °C

- Enhanced interference immunity in accordance with NAMUR recommendation NE21

- Conformal coating on all components

- Can be used at altitudes of up to 4 000 meters

Wide range of supported module types

- 16×AI, 8×AO HART, 16×DI, 16×DO etc.

Standard I/O terminal block

- For all 24 V signals AI, AQ, DI, DQ

Redundant configurations

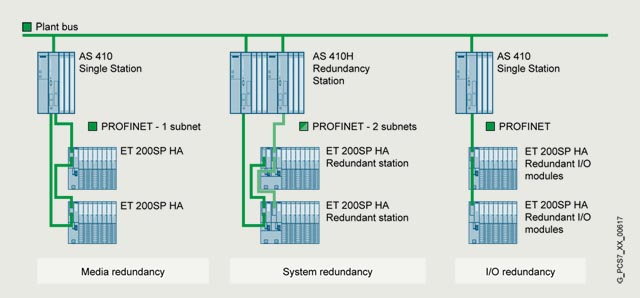

G_PCS7_XX_00617

SIMATIC ET 200SP HA, basic redundant configurations

The availability of the ET 200SP HA distributed I/O can if necessary be increased with redundant configurations. A number of different configurations are possible (the individual redundant configurations can also be combined):

Media redundancy

ET 200SP HA stations with 1 interface module each are connected to an automation system in a ring topology. At least one device in the ring takes on the role of the redundancy manager; the other devices in the ring are redundancy clients. The automation system is configured as MRP manager.

If the ring topology is interrupted, the ET 200SP HA stations in the system remain available.

One of the following functions is possible in runtime:

- Connecting and removing ET 200SP HA stations

- Replacing PROFINET cables

System redundancy

ET 200SP HA stations are connected to a redundant automation system. All components used redundantly are in continuous operation. If a redundancy partner fails, the function is maintained by transferring the master role or selecting a different communication path.

The ET 200SP HA stations remain available in the PROFINET IO system if a CPU or a PROFINET cable fails.

One of the following functions is possible in runtime:

- Connecting and removing ET 200SP HA stations

- Replacing PROFINET cables

- Replacing a CPU

More information