ENG_126403.XML

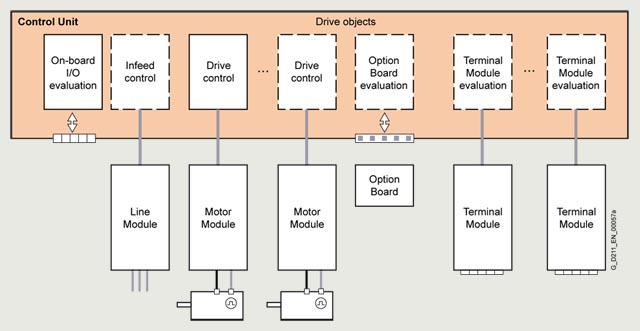

System architecture with a central Control Unit

Electronically coordinated individual drives work together to perform your drive tasks. In multi-axis drives, the individual drives are controlled from the higher-level control systems in such a way as to achieve the desired coordinated movement. This requires cyclic data exchange between the controller and the drives. A central Control Unit controls the drives for all connected axes and also establishes the technological links between the drives and/or axes. Since all the required data is stored in the central Control Unit, it does not need to be transferred. Inter-axis connections can be established within a Control Unit and easily configured in the SINAMICS Startdrive or STARTER commissioning tool using a mouse.

- The SINAMICS Control Unit can handle simple technological tasks by itself

- The CU310‑2 DP or CU310‑2 PN Control Units are used in conjunction with Power Modules and single-motor drives.

- The CU320‑2 DP or CU320‑2 PN Control Units are used in conjunction with all Motor Modules or Line Modules for single or multi-motor drives.

- Sophisticated motion control tasks can be implemented with the support of the more powerful D410‑2, D425‑2, D435‑2, and D445‑2 Control Units of SIMOTION D (graded according to performance).

You can obtain more information about SIMOTION in SiePortal and Catalog PM 21.

Each of these Control Units is based on an object-oriented SINAMICS standard firmware, which contains all common control modes and can be scaled to meet even the most advanced performance requirements.

The drive controls are supplied as ready-to-configure drive objects:

- Infeed Control for mains infeed

- Vector control

- Speed-controlled drives with high speed and torque stability in general machine and plant construction

- Particularly suitable for asynchronous motors

- Optimized pulse patterns for efficient motor/converter systems

- Servo control

- Drives with highly dynamic motion control

- Angular-locked synchronism with isochronous PROFIBUS/PROFINET

- For use in machine tools and clocked production machines

The most commonly used v/f control modes are stored in the "Vector control" drive object and are ideal for implementing even simple applications such as group drives with synchronous motors.

CompactFlash card

The functions of the drives are stored on a CompactFlash card. This card contains the firmware and parameter settings for all drives in the form of a project. The CompactFlash card can also hold additional projects, which means that the correct project can be accessed immediately when series machines of different types are commissioned. When the Control Unit has booted, the data on the CompactFlash card is read and loaded to the work memory.

The firmware is organized in objects. Drive objects are used to implement open-loop and closed-loop control functions for Line Modules, Motor Modules, Power Modules and other system components connected by DRIVE-CLiQ.

Drive objects

A drive object is a self-contained software function with its own parameters and, where appropriate, its own fault messages and alarms.

G_D211_XX_00057

Comprehensive package of open-loop and closed-loop control functions

A wide variety of standard functions such as setpoint input, data set changeover, controller optimization, kinetic buffering, etc. ensure a high degree of functional reliability and excellent flexibility when addressing the application.

Overview of key open-loop and closed-loop control functions

|

|

Closed-loop control types S120

|

Open-loop control types S120

|

Main functions S120 for booksize/chassis

|

Comment, note

|

|

Infeed Control

|

- Booksize

- Current control

with/without mains sensor - VDC control

without/with mains sensor

- Chassis

- Current control

with VSM10 - VDC control

with VSM10 - Network functionalities (island grids)

|

- Booksize/chassis

- Basic Mode

Rectification only - Smart Mode

Rectification and regenerative feedback

|

- Mains identification

- Controller optimization

- Harmonics filter

- Automatic restart

|

The mains sensor is the VSM10 Voltage Sensing Module;

"Current" is the line current;

3-phase with line frequency

|

|

Vector control

|

- Asynchronous motor

- Torque control with/without encoder

- Speed control with/without encoder

- Torque motor

- Torque control with encoder

- Speed control with/without encoder

- Asynchronous motor, torque motor

- Position control with encoder

- Reluctance motor

- Torque control with/without encoder

- Speed control with/without encoder

|

- Linear/parabolic V/f characteristic

- Constant-frequency V/f characteristic (textile)

- Independent voltage setpoint input

|

- Data set changeover

- Extended setpoint input

- Motor identification

- Current/speed controller optimization

- Technology controller

- Basic positioner

- Automatic restart

- Flying restart with/without encoder

- Kinetic buffering

- Synchronization

- Droop

- Brake control

|

Mixed operation with V/f control modes is possible; it is for this reason that the V/f control modes are stored only once in the "Vector control" drive object

V/f is not possible with reluctance motors.

More information on reluctance motors can be found in catalog D 81.1.

Position control can be selected as a function module from both Servo and Vector mode

Synchronous motors (1FK and 1FT) and linear motors can be operated only in Servo mode.

Permanent-magnet 1FW4 synchronous motors can be operated over the complete operating range in Vector control.

|

|

Servo control

|

- Asynchronous motor

- Torque control with/without encoder

- Speed control with/without encoder

- Synchronous motor, linear motor and torque motor

- Torque control with encoder

- Speed control with encoder

- All motor types

- Position control with encoder

|

- Linear/parabolic V/f characteristic

- Constant-frequency V/f characteristic (textile)

- Independent voltage setpoint input

|

- Data set changeover

- Setpoint input

- Motor identification

- Damping application

- Technology controller

- Basic positioner

- Brake control

|

Mixed operation with V/f control modes is possible; it is for this reason that the V/f control modes are stored only once in the "Vector control" drive object

Position control can be selected as a function module from both Servo and Vector mode.

|

Extended technology with SIMOTION

SIMOTION D Control Units support the coordinated motion control of multiple drives. Technology objects are implemented in addition to drive objects on these Control Units. These are grouped to form technology packages and make available extended Motion Control functions (e.g. synchronous operation, cam disk, path interpolation and others) or technological functions (e.g. a cam controller, a temperature or pressure control). The IEC 61131‑3-compliant PLC integrated in SIMOTION D Control Units means that they are not just capable of controlling sequences of motions, but the entire machine including HMI and I/Os.

You can obtain more information about SIMOTION in SiePortal and Catalog PM 21.

BICO technology

Every drive object contains a large number of input and output variables which can be freely and independently interconnected using Binector Connector Technology (BICO). A binector is a logic signal which can assume the value 0 or 1. A connector is a numerical value, e.g. the actual speed or current setpoint.

Basic positioner (EPOS)

The EPOS basic positioner provides powerful and precise positioning functions. Due to its flexibility and adaptability, the EPOS basic positioner can be used for a wide range of positioning tasks. The functions are easy to use during both commissioning and operation, and the comprehensive monitoring functions are very powerful. Many applications can be implemented without external position control systems.

More information about the basic positioner (EPOS) is provided in the section Technology functions.

EPOS is only available for SINAMICS S120 booksize and booksize compact.

SINAMICS Drive Control Chart (SINAMICS DCC)

SINAMICS DCC expands the scope of device functions by means of freely available closed-loop control, arithmetic and logic blocks and offers a means by which proprietary technological functions can be graphically configured in the SINAMICS drive system. In addition, local data processing in the drive supports the implementation of modular machine concepts and results in an increase in the overall machine performance.

More information about the Drive Control Chart (DCC) is provided in section Engineering tools.

SINAMICS Technology Extensions (SINAMICS TEC)

The SINAMICS TEC are configurable functions or Siemens technologies that can be added to extend firmware functions. The extensions implement high-performance and targeted application-specific tasks for different areas, e.g. storage and retrieval machines.

More information about Technology Extensions (TEC) is provided in section Technology functions.

Integral safety functions (Safety Integrated)

The Control Units support comprehensive safety functions.

The integrated safety functions are the Safety Integrated Basic Functions

- STO = Safe Torque Off

- SBC = Safe Brake Control

- SS1 = Safe Stop 1 (Time controlled)

and the Safety Integrated Extended Functions that require a license

- STO = Safe Torque Off

- SS1 with SBR/SAM = Safe Stop 1 with Safe Brake Ramp/Safe Acceleration Monitor

- SS2 = Safe Stop 2

- SBC = Safe Brake Control

- SOS = Safe Operating Stop

- SLS = Safely-Limited Speed

- SSM = Safe Speed Monitor

- SDI = Safe Direction

- SLA = Safely-Limited Acceleration

- SBT = Safe Brake Test

and Safety Integrated Advanced Functions

- SLP = Safely-Limited Position

- SP = Safe Position transmission

- SCA = Safe Cam

(Abbreviations in accordance with IEC 61800‑5‑2)

If the integrated safety functions are used, licenses, supplementary system components such as TM54F Terminal Modules, or suitable safety controls will be necessary.

More information about the integrated safety functions is provided in section Safety Integrated.

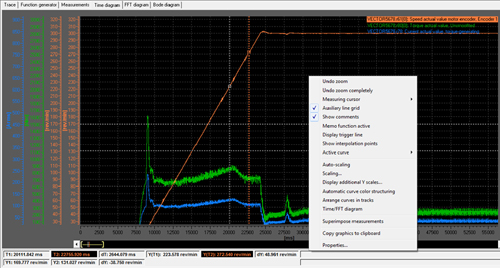

Diagnostics optimally supported by trace function

The time characteristics of input and output variables associated with drive objects can be measured by the integrated trace function and displayed using the STARTER commissioning tool. Several signals can be simultaneously traced. A recording can be triggered dependent on freely selectable boundary conditions, e.g. the value of an input or output variable.

S_D211_XX_00012

Taking the tour will redirect you to our new platform. You can always come back either by hitting back button on the browser or by opening the URL again.