ENG_149789.XML

P_ST70_XX_07438

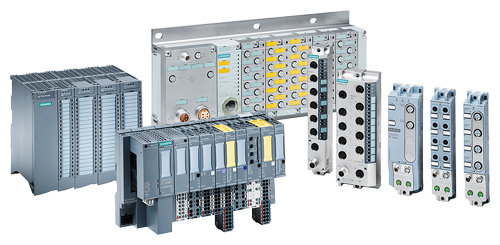

SIMATIC ET 200 offers the right solution for every application

SIMATIC ET 200 offers a broad selection of distributed I/O systems - for solutions in a control cabinet, directly on the machine, or in hazardous areas. The modular design allows the ET 200 systems to be scaled up and expanded in easy and small steps. Integrated add-on modules reduce costs while providing a broad range of applications. The following combinations are available for selection: digital and analog inputs/outputs, intelligent modules with CPU functionality, security systems, motor starters, pneumatic, frequency converter and various technology modules (e.g. for counting and positioning).

Communication over PROFIBUS and PROFINET, uniform engineering, transparent diagnostics facilities as well as the optimal connection to SIMATIC controllers and HMI devices demonstrate the unique consistency of Totally Integrated Automation.

PROFIBUS

PROFIBUS is the international standard (IEC 61158/61784) for the field area. It is the only fieldbus that allows communication in both production and process applications.

PROFIBUS allows the connection of field devices, such as remote distributed I/O devices or drives, to automation systems such as SIMATIC S7, SIMOTION, SINUMERIK or PCs.

PROFIBUS, built according to IEC 61158, is a powerful, open, and robust fieldbus system with short response times. PROFIBUS is available in different physics for different applications.

PROFIBUS DP (distributed I/O)

This is used to connect distributed field devices, e.g. SIMATIC ET 200 or drives with very fast response times. PROFIBUS DP is used when actuators/sensors are distributed on the machine or in the system (e.g. at field level).

PROFINET

PROFINET is the open and cross-vendor Industrial Ethernet standard (IEC 61158/61784) for automation.

Based on Industrial Ethernet, PROFINET enables direct communication of field devices (IO devices) with controllers (IO Controllers) up to isochronous drive controls for Motion Control applications.

Since PROFINET is built on the standard IEEE 802.3 Ethernet, it allows the continuous connection of devices from the field level up to the control level.

PROFINET thus permits uniform communication, allowing plant-wide engineering while using IT standards, e.g. Web server or FTP, down to the field level. Proven fieldbus systems such as PROFIBUS or AS-Interface can be integrated in a simple way and with no modifications to existing equipment.

AS-Interface

AS-Interface is the international standard (IEC 62026/EN 50295) which presents a very low-cost alternative to cable harness sensors and actuators in the field area with a simple two-wire line. This two-wire line also carries the power supply for each participant. Hence, the AS-Interface is the ideal partner for the PROFIBUS DP fieldbus.

AS-i communications modules in ET 200SP enable the flexible combination of AS-Interface and distributed I/O. AS-Interface transmits standard data and safety data up to PL e / SIL 3 in the same AS-i network. AS-Interface is not only suitable for efficient transmission of digital and analog standard I/O signals but also ideal for the user-friendly connection of EMERGENCY STOP buttons and protective doors.

IO-Link

The communication standard IO-Link permits the intelligent connection of sensors and switchgear to the control level. IO-Link facilitates the integration of all components in the control cabinet and on the field level - for maximum integration and seamless communication on the final meters to the process.

IO-Link solutions from Siemens ensure maximum precision and cost-effectiveness in any production system. IO-Link is completely integrated in Totally Integrated Automation (TIA) and offers many advantages.

- The open standard permits the networking of devices from different manufacturers

- Simple wiring facilitates the installation process

- Reduced wiring effort saves time and money during installation

- Efficient engineering facilitates configuration and commissioning

- High-speed diagnostics ensures short plant standstill times and high plant availability

- High process transparency permits, for example, efficient power management