ENG_107088.XML

P_NC01_XX_00983

P_NC01_XX_00983

P_NC01_XX_00978

P_NC01_XX_00978

SINUMERIK NCU 730.3B PN and Numeric Control Extension NX15.3 (from left)

Platform Concept and Totally Integrated Automation

All SINAMICS versions are based on a platform concept. Common hardware and software components, as well as standardized tools for design, configuration and commissioning tasks, ensure high-level integration across all components.

SINAMICS handles a wide variety of drive tasks without system gaps. The different SINAMICS versions can be easily combined with each other.

SINAMICS is part of the Siemens "Totally Integrated Automation" concept. Integrated SINAMICS systems covering engineering, data management and communication at automation level, ensure low-maintenance solutions with the SINUMERIK, SIMOTION, and SIMATIC control systems.

P_D211_XX_00171

SINAMICS S120 blocksize, booksize, and chassis formats

All formats can be combined freely

The different formats of SINAMICS S120 can be combined freely thanks to their innovative drive architecture with DRIVE-CLiQ interfaces, e.g. Line Modules in chassis format can be freely combined with Motor Modules in booksize format for multi-axis applications with high total output.

G_D211_XX_00097

Modular system for demanding drive tasks

SINAMICS S120 solves demanding drive tasks for a wide range of industrial applications and is, therefore, designed as a modular system. Users can choose from many different harmonized components and functions to create a solution that best meets their requirements. SIZER, a high-performance configuring tool, makes it easier to choose and determine the optimum drive configuration. This is possible due to the consistent subdivision of the drive in hardware and software function objects, which ensures that the power unit and Control Unit are isolated from each other.

The power units are selected in accordance with the requirements for energy consumption for the motion of the working machine and for exchange of energy with the power supply network. The Control Unit is selected in accordance with the number of drives to be controlled and the performance required. Communication between the Control Unit and power unit takes place very simply via the digital system interface DRIVE‑CLiQ.

SINAMICS S120 is enhanced by a wide range of motors. Whether synchronous or asynchronous, all motor types are supported by SINAMICS S120.

Particularly suitable for multi-axis applications

Coordinated drives that carry out a drive and motion task together are used in many mechanical and plant engineering applications, These require drives with a connected DC link, which allows cost-saving energy balancing between braking and driving axes.

SINAMICS S120 features Line Modules (infeed modules) and Motor Modules (inverter modules) covering a wide power range which, having been designed for seamless integration, pave the way for compact multi-axis drive configurations.

New system architecture with a central Control Unit

Electronically coordinated single drives work together to perform the drive tasks. Higher-level computerized numerical controls such as SINUMERIK operate the drives to achieve the required coordinated movement. This requires cyclic data exchange between the CNC and all the drives. This exchange usually took place via a fieldbus, which required a great deal of time and effort for installation and configuration. SINAMICS S120 takes a different approach. A central Control Unit controls the drive for all connected axes and also establishes the technological links between the drives and/or axes. Since all the required data is stored in the central Control Unit, it does not need to be transferred. Inter-axis connections can be established within a Control Unit. They can be easily configured in the STARTER commissioning tool or with the drive commissioning wizard integrated in the SINUMERIK HMI interface. Of course, a number of Control Units can be interconnected to create an expanded group if your application exceeds the computing performance of one Control Unit.

Simple technological tasks can be carried out automatically by the SINAMICS S120 Control Unit. For more complex numerical tasks, they are replaced by powerful modules from the SINUMERIK product range.

As well as motion control, coordinate transformation and logic functions, these products also integrate the SINAMICS drive control. The NCUs of SINUMERIK can be positioned in or alongside the SINAMICS S120 drive group and connected via DRIVE-CLiQ. For the implementation of distributed solutions, the NCU can also be placed up to 100 m away from the drive group. In case of application solutions that have a greater number of motion axes in the machine kinematics, the system base units can be expanded with the additional Numeric Control Extensions NX10.3/NX15.3.

DRIVE-CLiQ – the digital interface between all components

All SINAMICS S120 drive system components, including the motors and encoders, are interconnected by a shared serial interface called DRIVE-CLiQ. The standardized cables and connectors reduce the variety of different parts and cut storage costs.

Sensor Modules (converter boards) for converting standard encoder signals to DRIVE-CLiQ are available for motors and encoders without a DRIVE-CLiQ interface or for retrofitting applications.

Swift and automatic: The electronic rating plate

All SINAMICS S120 components with a DRIVE‑CLiQ interface have an electronic rating plate that contains all the relevant data about that particular component. For motors, for example, these data include the parameters of the electric equivalent circuit diagram and characteristic values for the built-in motor encoder. The Control Unit records this component-specific data automatically via DRIVE-CLiQ so that it does not need to be entered during commissioning or when the equipment is replaced.

In addition to the technical data, the electronic rating plate includes logistical data such as the manufacturer ID, article number, and globally unique ID. Since these data can be called up electronically on site or remotely, all the components used in a machine can always be individually identified, which helps simplify servicing.

The following overviews feature the SINAMICS S120 components that are primarily used for multi-axis drive tasks.

G_NC01_XX_00524

Example: SINAMICS S120 drive system with SINUMERIK 840D sl

Control Units

P_D211_XX_00215

P_D211_XX_00213

P_D211_XX_00216

P_D211_XX_00175

Control Units CU310-2 PN, Control Units CU310-2 DP, CU320-2 PN, CU320-2 DP, NCU 730.3 PN and Numeric Control Extension NX15.3

Control Units for drive control in SINUMERIK, the Numeric Control Extensions NX and the CU320-2

SINAMICS S120 CU320-2 Control Unit

These central Control Units can be used to create links between individual drives and implement simple technology functions.

The CU320-2 Control Unit has been designed to control multiple drives. With the SINUMERIK, up to 6 drives can be operated in servo control mode on one Control Unit.

The Control Units in the SINUMERIK CNCs are available in various rating classes for implementing coordinated motion control in a multi-axis interpolation grouping on machine tools:

SINUMERIK 840D sl

- NCU 710.3B PN/NCU 720.3B PN/NCU 730.3B PN with integrated drive control for up to 6 axes

- Numeric Control Extensions NX10.3/NX15.3 for extended control of up to 3/6 axes

Commissioning and diagnostics of the various Control Units in combination with the power components is performed in conjunction with the SINUMERIK using the drive wizard of the HMI Operate commissioning tool. Alternatively, the drive can be commissioned using the STARTER commissioning tool.

For further information about STARTER, see Engineering software.

Motor Modules

The Motor Modules are the final controlling element for the motor and feature a DC link that is fed from a DC voltage and, as an output, an inverter for feeding the motor.

P_D211_XX_00352

SINAMICS S120 Motor Modules in booksize format C/D types

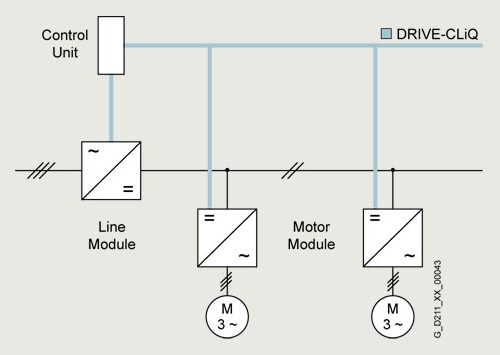

G_D211_XX_00043

Motor Modules are designed for multi-axis drives and are controlled by a SINUMERIK NCU or a CU320 Control Unit. The Motor Modules are interconnected through a common DC bus. Since the Motor Modules share the same DC link, they can exchange energy with one another, i.e. if one Motor Module operating in generator mode produces energy, the energy can be used by another Motor Module operating in motor mode. The voltage-source DC link is supplied with mains voltage by a Line Module.

Line Modules

Line Modules generate a DC voltage from the line voltage and supply Motor Modules with energy via the voltage-source DC link. The SINAMICS S120 range contains the following types of Line Modules:

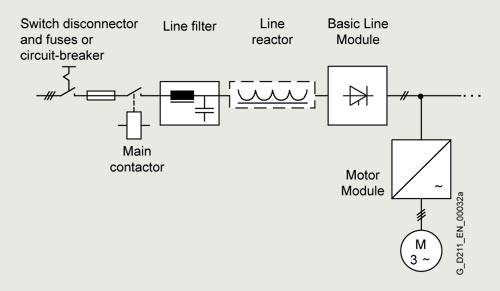

Basic Line Modules

Basic Line Modules are designed only for infeed operation, i.e. they are not capable of recovering energy to the line supply. If regenerative energy is produced, e.g. when drives brake, it must be converted to heat by means of a Braking Module and a braking resistor. When a Basic Line Module is used as the infeed, the matching line reactor must be installed. A line filter can be installed optionally in order to comply with the EN 61800-3 Category C2 limits.

G_D211_XX_00032

Smart Line Modules

Smart Line Modules can feed energy to the DC link of a drive group through a non-stabilized converter and also feed back the generated excess energy into the power supply system. The line voltage variations are mirrored proportionately in the DC link voltage. Braking Modules and braking resistor are required only if the drives need to be decelerated in a controlled manner for island supply systems or after a power failure (i.e. when energy cannot be recovered to the supply). When a Smart Line Module is used as the infeed, the matching line reactor must be installed. A line filter can be installed optionally to restrict the interference voltage level to Class C2 limits (EN 61800‑3).

G_D211_XX_00033

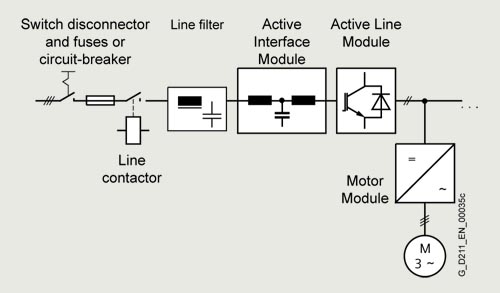

Active Line Modules

Active Line Modules can supply energy to the DC link rail and return regenerative energy to the supply system. In contrast to Smart Line Modules, Active Line Modules generate a regulated DC voltage which remains constant despite fluctuations in the line voltage. In this case, the line voltage must remain within the permissible tolerance range. Braking Modules and braking resistors are required only if the drives need to be decelerated in a controlled manner even after a power failure (when energy cannot be recovered to the supply). Active Line Modules draw a virtually sinusoidal current from the supply which virtually rules out any harmful harmonics.

Active Line Modules in chassis format

All the components required to operate an Active Line Module are integrated in the Active Interface Module.

G_D211_XX_00035

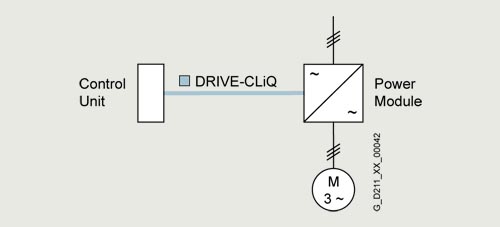

Power Modules

The simplest version of a SINAMICS S120 drive system comprises a CU310‑2 Control Unit and a Power Module. A mains rectifier, a voltage-source DC link and an inverter for supplying a motor are integrated in the Power Module.

P_D011_XX_00578

Power Module in blocksize format

G_D211_XX_00042

Power Modules are designed for single drives which are not capable of regenerating energy to the supply. Generated energy produced during braking is converted to heat via braking resistors.

Power Modules can also be operated by a CU320-2 Control Unit or a drive control integrated in SINUMERIK, e.g. in configurations where a single drive has been added to a multi-axis drive group. In this case, the Power Modules in blocksize format must be equipped with the CUA31 Control Unit Adapter. This is connected with the CU320-2 Control Unit or the NCU in SINUMERIK using DRIVE‑CLiQ. Power Modules in chassis format are directly connected to the Control Unit using a DRIVE-CLiQ cable.

The following versions are available:

- Motor Modules and Line Modules in booksize and chassis formats

- Power Modules in blocksize and chassis formats

- Motor Modules in booksize compact format

- SINAMICS S120 Combi

Booksize format

Booksize format units are optimized for multi-axis applications and are mounted adjacent to one another. The connection for the shared voltage-source DC link is an integral feature.

Internal air cooling

In this standard solution, the power loss from the electronics and power units of the drive components is removed by natural cooling or by a forced-ventilation system and routed to the interior of the control cabinet.

Chassis format

Higher-output units (approximately 100 kW and above) are constructed in chassis format. These devices are available as Line Modules and Motor Modules. Chassis format units are cooled by an internal air cooling circuit.

P_NC01_XX_00771

Blocksize format

The units in blocksize format are optimized for single-axis applications.

The CU310-2 DP/CU310-2 PN Control Units or CUA31 Control Unit Adapters can be snapped on directly. The units are cooled by an internal air cooling circuit.

P_D011_XX_00566

Power Module with Control Unit and Operator Panel plugged in

SINAMICS S120 Combi

SINAMICS S120 Combi is a very compact and rugged drive system for compact turning and milling machines.

SINAMICS S120 Combi integrates a line infeed with regenerative feedback capability, power units for spindle and feed motors as well as a TTL encoder interface into a single Power Module.

Special features are the minimum space requirement in the control cabinet, low energy requirement thanks to state-of-the-art 400-V technology, and perfected expendability using additional Motor Modules in booksize compact format.

The use of Motor Modules in booksize compact format is only permissible in combination with SINAMICS S120 Combi.

An intelligent DRIVE-CLiQ interface is provided for cabling.

P_NC01_XX_00957

SINAMICS S120 Combi

Additional system components

The structure of the drive system is defined by the selected Control Unit, Line Module, and Motor Modules or Power Module. An optimal solution can be obtained for the drive task using these system components.

Additional system components can be installed to expand the system's scope of functions and adapt it perfectly to the drive task in question.

System components are divided into the following categories:

-

DC link components

such as Braking Modules and braking resistors

Further DC link components are optionally installed to stabilize the DC link voltage and/or to support the electronics power supply.

-

Supplementary system components

such as Terminal Modules for expanding the I/O interfaces to the machine interface

-

Encoder system connection

for connecting various types of encoders to SINAMICS S120

-

Line-side power components

such as fuses, contactors, reactors, and filters for switching the power supply and meeting EMC requirements.

Energy efficiency

The SINAMICS S120 drive system saves energy by recovering energy from the axes and using it within the DC link group of a multi-axis configuration and by feeding it back into the supply system. Even at full infeed capacity, no unnecessary heat is generated in the control cabinet. With intelligent compensation of capacitive and inductive reactive currents, SINAMICS S120 also ensures that no unnecessary power losses occur in the power supply and that no current harmonics occur. This not only prevents detrimental effects on other loads, but it also reduces the heat generated in the control cabinet.

The SINAMICS S120 components have been developed for installation in cabinets

They have the following features and characteristics:

- User friendliness

- Simple assembly and wiring

- Practical connection system, cable routing in accordance with EMC requirements

- Uniform design

- Contiguous assembly

Rugged units

The SINAMICS units are equipped as standard with varnished or partially varnished modules for enhanced robustness.

The varnish coating protects the sensitive SMD components against corrosive gases, chemically active dust and moisture.

SINUMERIK and SINAMICS automation system components

G_NC01_XX_00523