ENG_252194.XML

Functional safety of machines and plants – Basic safety requirements in the manufacturing industry

In order to protect people and the environment in many industrial applications in the manufacturing and process industries, machines and plants must meet fundamental safety requirements. The Machinery Directive applies in the EU. In addition to design solutions, automation systems and components are also expected to perform safety-related tasks. This means that the life and health of people and the physical integrity of capital goods and the environment depend on the proper operation of these systems and components, on "functional safety".

With the introduction of the uniform European Single Market, national standards and regulations affecting the technical realization of machines were consistently harmonized. This involved defining basic safety requirements which address, on the one hand, machine manufacturers in terms of the free movement of goods (Article 95) and, on the other hand, machine operators in terms of industrial safety (Article 137).

EU Directives:

- Define requirements which must be met by plants and their operating companies in order to protect the health of people and the quality of the environment

- Include standards for health & safety at work (minimum requirements)

- Define product requirements (e.g. for machines) to protect the health and safety of consumers

- Differentiate between the requirements which must be met for the implementation of products in order to ensure the free movement of goods and the requirements which must be met for the use of products

- Similar requirements apply in many other countries and markets

G_IC01_XX_00543

Safety requirements imposed on machines and plants

Objective of the standards

It is the objective of safety technology to minimize as far as possible the hazards from technical facilities for people and the environment while restricting no more than absolutely necessary the scope of industrial production, the use of machines or the production of chemical products.

Production automation is governed in particular by the following standards:

- IEC 62061 and

- ISO 13849‑1

The IEC 62061 standard

The IEC 62061 standard "Safety of machines – Functional safety of electrical, electronic and programmable electronic control systems" defines comprehensive requirements. It includes recommendations for the design, integration and validation of safety-related electrical, electronic and programmable electronic control systems (SRECS) for machines. For the first time, one standard covers the entire safety chain, from the sensor to the actuator. The Safety Integrity Level, or SIL for short, is defined as the application parameter for this standard.

Requirements with respect to the capacity of non-electrical – e.g. hydraulic, pneumatic, or electromechanical – safety-related control elements for machines are not specified by the standard.

P_IC01_XX_00906

Safety of machines and systems

The ISO 13849‑1 standard

ISO 13849‑1 "Safety of machines - Safety-related components of controls – Part 1: General principles" replaced EN 954‑1 at the end of 2011. It considers the complete range of safety functions with all the devices which are involved in their performance. ISO 13849‑1 also makes a quantitative analysis of the safety functions. The standard describes how to determine the Performance Level (PL) for safety-relevant parts of control systems on the basis of architectures specified for the intended service life.

When combining several safety-related parts to form a complete system, the standard explains how to determine the resulting PL. It can be applied to safety-related parts of control systems (SRP/CS) and all types of machines, regardless of the technology and energy used, e.g. electrical, hydraulic, pneumatic or mechanical.

Safety Integrated – Integrated safety technology from a single source

P_IC01_XX_00789

Safety Integrated

The following applies equally for machine manufacturers and the companies which operate their machines: Maximum possible safety for personnel and machines. The solution: our Safety Integrated concept based on Totally Integrated Automation. Whether for simple safety functions or highly complex tasks – our portfolio offers you maximum safety.

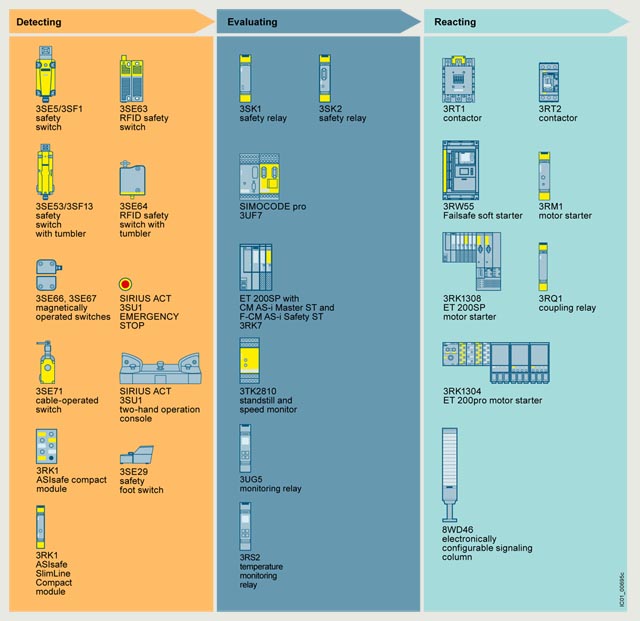

Safety Integrated is a unique, complete and consistent range of safety products covering all safety-related tasks – from detecting, evaluating and reacting, from switches and control systems to operating mechanisms (see graphic below). Our products meet the safety requirements in force in industry, including IEC, ISO, NFPA and UL, and are certified in accordance with the latest safety standards.

All Safety Integrated products or systems can be seamlessly integrated in the standard automation environment. They are therefore particularly flexible and economical, reduce engineering time, increase plant availability and enable practice-related machine operation.

Designing a safety function

A safety chain normally comprises the following functions: detect, evaluate and react. In detail this means:

- Detect = the detection of a safety requirement with corresponding sensors, such as EMERGENCY STOP or position switches

- Evaluate = the detection of a safety requirement and the reliable initiation of a reaction, e.g. shutting down the enabling circuits

- React = shutting down the hazard using suitable motor switching devices such as contactors, fail-safe motor starters, or fail-safe soft starters

G_NSC0_XX_00719

Possible configuration of a safety function

As a partner for all safety requirements, we not only support you with the respective safety-related products and systems, but also consistently provide you with the most current know-how on international standards and regulations. Machine manufacturers and plant managers are offered a comprehensive training portfolio as well as services for the entire life cycle of safety-related systems and machines.

For more information, see www.siemens.com/safety-integrated.

Safety Evaluation in the TIA Selection Tool

S_IC01_XX_00184

Safety Evaluation

The safety evaluation for the standards IEC 62061 and ISO 13849‑1 is performed quickly and easily, directly in the TIA Selection Tool. In addition to the fast and safe calculation of machine safety functions – from the definition of the system structure to the selection of components – this enables shared data management during all project phases. Take the next step in the digital design of machinery and equipment with Safety Evaluation in the TIA Selection Tool.

In addition, the functionalities of the proven Safety Evaluation Tool are still available. It determines the achieved safety integrity (SIL/PL) step-by-step. You receive the results as a standard-compliant report that can be integrated in the documentation as proof of safety.

Your advantages at a glance:

- Automatic calculation in accordance with current standards

- Fast results: Standard-compliant report

- Less time needed to evaluate the safety functions

- Fast access to the latest product data

- User-friendly archiving: Projects can be saved and called up again as required

- Selection menus for determining diagnostic coverage (DC) and common cause failures (CCF).

- Different operating cycles can be input when used in a 2-channel configuration

- Failure rate calculation

For more information, see www.siemens.com/safety-evaluation-tool.

G_NSB0_XX_01822

Safety Integrated

SIRIUS Safety Integrated

Our SIRIUS Safety Integrated controls are a central element of the Siemens Safety Integrated concept. Whether for fail-safe detecting, commanding and signaling, monitoring and evaluating or starting and reliable shutting down – our SIRIUS Safety Integrated controls are experts at performing safety tasks in your plant.

SIRIUS Safety Integrated uses fail-safe communication via standard fieldbus systems, such as ASIsafe via AS‑Interface and PROFIsafe via PROFIBUS and PROFINET, to solve even networked safety tasks of greater complexity. This opens the door for flexible safety solutions for compact machines or large-scale plants.

Implementation of many typical safety applications, see Application Manual for SIRIUS Safety Integrated.

G_IC01_XX_00695

SIRIUS Safety Integrated

Monitoring with safe evaluation units from the 3SK series

The fail-safe evaluation devices of the 3SK device series are perfectly suited for evaluating safety switches of the 3SE product family. These are not only suitable for simple position switches, but can also be used easily and without problems with non-contact position switches and switches with tumblers. The highest safety levels SIL 3 according to IEC 62061 and PL e according to ISO 13849‑1 can be achieved.

Movable guards must be equipped with an interlocking or an interlocking with tumbler (guard locking device). These are two different functions in machine safety:

- The interlocking is a safety switch that shuts down the machine as soon as the protective cover to which it is attached is opened, making it a safety function.

- The tumbler (guard locking device) does not have to be a safety function. It holds the protective hood closed until the dangerous movement has come to a standstill. It can be mounted in addition to the interlocking.

G_IC01_XX_00898

Monitoring with fail-safe evaluation units

Notes:

For more information, see http://support.automation.siemens.com/ww/view/com/35443942.

Safety switches, see Position and safety switches.

Monitoring with simple position switches, see SIRIUS 3SE5 mechanical position switches → Monitoring with safe evaluation devices of the 3SK series.

Using SIRIUS 3RT contactors with fail-safe controllers and safety relays

Safety relays and fail-safe controllers work perfectly with SIRIUS contactors optimized for safety application regardless of their size:

- In the low performance range with 3RT201 or 3RT202 contactors with DC operating mechanism

- In the medium performance range with 3RT203 or 3RT204 contactors with solid-state operating mechanism and fail-safe control input

- In the high performance range with 3RT105, 3RT106 or 3RT107 contactors with solid-state operating mechanism and fail-safe control input

They offer the following advantages:

- Reduced current load on the controller outputs

- Minimization of wear for mechanical relays on controllers or safety relays

- Coupling links between controllers and contactors are no longer required

G_IC01_XX_00534

Combination of SIRIUS 3RT contactors with fail-safe controllers and safety relays

|

|

|

Type

|

|

SIRIUS Safety Integrated

|

|

|

G_IC03_XX_03953

3SK111

|

3SK safety relays

- Key modules of a consistent and cost-effective safety chain

- Can be used for all safety applications thanks to compliance with the highest safety requirements (SIL 3 according to IEC 62061 or PL e according to ISO 13849‑1)

- Suitable for use all over the world through compliance with all globally established certifications

|

|

|

SIRIUS 3SK1 Standard basic units

- Simple, compact devices for all important requirements for monitoring safety sensors and actuators

|

3SK111

|

|

G_IC03_XX_03959

3SK112

|

SIRIUS 3SK1 Advanced basic units

- Multifunctional series of safety relays with safe relay outputs, semiconductor outputs or time-delayed outputs for:

- EMERGENCY STOP monitoring

- Protective door monitoring

- Monitoring of non-floating sensors such as light arrays, laser scanners, etc.

- Monitoring of two-hand operation consoles

- Monitoring of equivalent (NC/NC) and antivalent (NO/NC) sensors

- Setting by means of DIP switch

|

3SK112

|

|

G_IC03_XX_08721

3SK2

|

SIRIUS 3SK2 basic units

- Series of safety relays that can be configured by software, with semiconductor outputs and independent output functions for:

- EMERGENCY STOP monitoring

- Protective door monitoring

- Protective door monitoring with tumbler

- Monitoring of non-floating sensors such as light arrays, laser scanners, etc.

- Monitoring of two-hand operation consoles

- Monitoring of equivalent (NC/NC) and antivalent (NO/NC) sensors

- Muting

- Communication via PROFINET (optional)

|

3SK2

|

|

G_IC03_XX_03958

3SK121

|

Expansion units

- 3RO and 4RO output expansions for SIRIUS 3SK1 Standard basic units, SIRIUS 3SK1 Advanced basic units and SIRIUS 3SK2 basic units

- 3RQ1 output expansions up to SIL 3/PL e for SIRIUS 3SK1 Standard basic units, SIRIUS 3SK1 Advanced basic units and SIRIUS 3SK2 basic units

- Input expansion for SIRIUS 3SK1 Advanced basic units

- Power supply for SIRIUS 3SK1 Advanced basic units

- Integration of 3RM1 motor starters possible and, therefore, simple integration of a main circuit component in a system configuration of the safety relays. There is no need for complex wiring between the safety evaluation unit and the actuator.

- Expansion of the Standard device series by means of wiring

- Expansion of the SIRIUS 3SK1 Advanced and SIRIUS 3SK2 device series by means of wiring or without wiring outlay by means of 3ZY12 device connectors

|

3SK121,

3SK122,

3SK123

|

|

P_IC01_XX_00843

3TK2810-1BA41

|

3TK2810 safety relays

- Further modules of a consistent and cost-effective safety chain

- Can be used for all safety applications thanks to compliance with the highest safety requirements (SIL 3 according to IEC 62061/IEC 61508 or PL e according to ISO 13849‑1)

- Suitable for use all over the world through compliance with all globally established certifications

Safe standstill monitoring with 3TK2810‑0

- Monitoring without external sensors

- Universal use in applications possible

Safe speed monitoring with 3TK2810‑1

- Monitoring of speed with encoders and proximity switches possible

- Easy diagnostics options via display

- Integrated monitoring of a protective door with spring-loaded interlocking

|

3TK2810

|

|

P_NSW0_XX_00910

K45F

|

G_IC03_XX_16543

SC17.5F

|

AS‑Interface safety modules

- Complete portfolio of ASIsafe modules

- For connection of safety switches with contacts (e.g. position switches)

- Degree of protection IP65/IP67 or IP20

- Especially compact dimensions, with widths from 17.5 mm

- Up to four safe inputs per module

- Standard outputs are available on the module in addition

- Up to SIL 3/PL e

Your advantage: Easy integration of safe signals both in the control cabinet or in the field

|

3RK1

|

|

P_IC01_XX_00652

CM AS-i Master ST and F-CM AS-i Safety ST

|

CM AS‑i Master ST and F‑CM AS‑i Safety ST for ET 200SP

The CM AS‑i Master ST and F‑CM AS‑i Safety ST modules are plugged into an ET 200SP configuration, and they connect an AS-i network, including safety-related inputs and outputs, with the controller.

- Single, double and multiple masters possible

- Per CM AS‑i Master ST up to 496 DI/496 DQ/124 AI/124 AQ possible

- Per F‑CM AS‑i Safety ST up to 31 safe input signals (2-channel)/16 safe output channels possible

- Configuration in the TIA Portal/STEP 7

- Plant-wide safety programming of the F‑CPU via SIMATIC Distributed Safety/Safety Advanced

- Integrated diagnostics

- No other programming tools required

Your advantage: Modular connection of fail-safe AS-i networks with system-wide programming in SIMATIC and SINUMERIK controllers.

|

6ES7, 3RK7

|

|

G_IC03_XX_28892

3RT203.-1S.30

G_IC03_XX_28957

3RT204.-1S.30

|

SIRIUS 3RT contactors, 3-pole

18.5 to 55 kW

- Solid-state operating mechanism with fail-safe control input for safety-related applications up to SIL 2/PL c with one contactor or SIL 3/PL e with two contactors

- 3RT20 only for motor loads

- Version with auxiliary switch can be extended either on the front or on the side

|

3RT20

|

|

G_IC03_XX_21505

3RT1..-.S.36

|

55 to 250 kW or 690 A

- Solid-state operating mechanism with fail-safe control input for safety-related applications up to SIL 2/PL c with one contactor or SIL 3/PL e with two contactors

- 3RT10 for motor loads or 3RT14 for weak or non-inductive loads

- Version with removable lateral auxiliary switches or permanently mounted auxiliary switches

|

3RT10,

3RT14

|

|

G_IC03_XX_27845

3RQ1

|

SIRIUS 3RQ1 force-guided coupling relays, fail-safe up to SIL 3/PL e

- For safe coupling up to SIL 3/PL e of control signals to and from a control system or as an output expansion for the SIRIUS 3SK safety relays

- Wide voltage ranges from 24 to 240 V AC/DC

- All versions with real load contacts, also in the NC circuit

- International standards and certifications including CE, UL/CSA, EAC, railway approvals, and more

|

3RQ1

|

|

G_IC03_XX_27593

3RW55

|

3RW55 Failsafe soft starters

- 3RW55 soft starters for safety-oriented tripping

- SIL 1/PL c without additional safety evaluation unit or contactor with direct wiring of an EMERGENCY STOP to F‑DI

- SIL 3/PL e with an additional contactor and safety evaluation unit or F‑PLC

- For motors up to 315 kW (at 400 V) in the standard (inline) circuit or 560 kW (at 400 V) in the inside-delta circuit

|

3RW55

|

|

G_IC03_XX_03996

3RM1

|

3RM1 Failsafe motor starters

- Motor starters for safety-oriented tripping as 3RM11 direct-on-line starters or 3RM13 reversing starters

- Compact devices with 22.5 mm width comprising combinations of relay contacts and power semiconductors (hybrid technology) and an electronic overload relay

- For switching three-phase motors up to 3 kW (at 400 V) and resistive loads up to 10 A at AC voltages up to 500 V under normal operating conditions

- Safety-related shutdown according to SIL 3 or PL e by shutting down the control supply voltage or control inputs possible without additional devices in the main circuit

- Combination with 3SK safety relay through conventional wiring or 3ZY12 device connectors

- Simple wiring and collective shutdown with device connectors in assemblies; there is no further need for complex looping of the connecting cables

|

3RM1

|

|

G_IC03_XX_18956

3RK1308-0CB00-0CP0

|

ET 200SP fail-safe motor starters

- Fully integrated into the ET 200SP I/O system (including TIA Selection Tool and TIA Portal)

- Fully pre-wired motor starters for switching and protecting any AC loads up to 5.5 kW from 48 V AC to 500 V AC

- Less space required in the control cabinet (20 to 80%) as a result of greater functional density (direct-on-line and reversing starters in same width)

- Longer service life and reduced heat losses thanks to hybrid technology

- Self-assembling 32 A power bus, i.e. the load voltage is only fed in once for a group of motor starters

- High degree of flexibility when it comes to safety applications via SIMATIC F‑CPU or 3SK safety relays up to SIL 3 or PL e

- Diagnostics capability for active monitoring of the switching and protection functions

- Digital inputs can optionally be used via a 3DI/LC module

|

3RK1

|

|

P_ST70_XX_03756

ET 200pro Safety

|

ET 200pro Safety motor starters Solution

PROFIsafe Safety motor starters Solution are often found in safety applications of the more complex type that are interlinked. In this case, a safe control system is used with the PROFINET or PROFIBUS bus systems with the PROFIsafe profile.

It comprises:

- PROFIsafe modules

- Disconnecting modules

- Standard motor starters

- High Feature motor starters

|

3RK1

|

|

P_IC01_XX_00657

SIMOCODE pro V

|

SIMOCODE pro motor management and control devices

- Flexible, modular motor management system for motors with constant speeds in the low-voltage range

- Provides an intelligent interface between the higher-level automation system and the motor feeder

- Multi-functional, electronic full motor protection which is independent of the automation system

- Integrated control functions for the motor control

- Detailed operating, service and diagnostics data

- Open communication via PROFIBUS DP, PROFINET/OPC UA, Modbus RTU or EtherNet/IP

- Safety relay function for the fail-safe disconnection of motors up to SIL 3 according to IEC 62061/IEC 61508 or PL e according to ISO 13849‑1

Fail-safe digital modules

- DM‑F Local for direct assignment between a fail-safe hardware shutdown signal and a motor feeder

- DM‑F PROFIsafe for when a fail-safe controller (F‑CPU) creates the fail-safe signal for the disconnection

|

3UF7

|

|

P_IC01_XX_00658

SIMOCODE pro S

|

|

G_IC03_XX_31668

3UG5

|

3UG5 monitoring relays

- For electrical and mechanical quantities and the following functions:

- Line monitoring relay (phase sequence and failure)

- Monitoring of current and voltage, power factor, active current, power

- Undershooting and/or overshooting of liquid levels or speed limits

- Enable constant monitoring of all important characteristic quantities that provide information about the performance reliability of the plant

- Direct, safe disconnection of the affected plant components up to SIL 1 according to IEC 62061/IEC 61508 or PL c according to ISO 13849‑1 as well as alarms (e.g. by activating a warning lamp)

|

3UG5

|

|

G_IC03_XX_28004

3RS2

|

Temperature monitoring relays

- Relay for fail-safe monitoring of temperatures in solid, liquid and gaseous media

- Direct, safe disconnection of the affected plant components up to SIL 1 according to IEC 62061/IEC 61508 or PL c according to ISO 13849‑1 as well as alarms

|

3RS2

|

|

P_NSW0_XX_01622

3SE51

|

Mechanical position switches

- Easy assembly thanks to modular design

- Solid, rugged design

- Special versions are easily generated and quickly available, also in combination with standard modules

- With a 3SE51/3SE52 position switch, it is possible to achieve SIL 1 according to IEC 62061/IEC 61508 or PL c according to ISO 13849‑1.

- SIL 2/PL d and SIL 3/PL e can be achieved by using a second 3SE51/3SE53 position switch.

|

3SE51, 3SE52

|

|

P_NSW0_XX_01623

3SE53

|

Mechanical safety switches

- With separate actuator, hinge switch, or separate actuator and tumbler

- With a position switch, it is possible to achieve SIL 2 according to IEC 62061/IEC 61508 or PL d according to ISO 13849‑1.

- SIL 3 according to IEC 62061/IEC 61508 or PL e according to ISO 13849‑1 can be achieved by using a second 3SE51 or 3SE52 position switch.

- Version in various sizes made of metal or plastic

- In the case of safety switches with tumbler, versions in the high degree of protection IP69

- Version with integrated ASIsafe electronics available for all enclosure designs

|

3SE51,

3SE52,

3SE53,

3SF1

|

| |

Non-contact safety switches

|

|

|

P_IC02_XX_00432

3SE66, 3SE67

|

Magnetically operated switch

- Small, compact, safe

- Simple installation even in restricted spaces thanks to connector versions

- Two safety contacts and one signaling contact enable simple diagnostics at the maximum safety level

|

3SE66,

3SE67

|

|

P_IC02_XX_00066

3SE63

|

RFID safety switches

- Long service life due to non-contact switching

- Only one switch required for the maximum safety level SIL 3 according to IEC 62061/IEC 61508 or PL e according to ISO 13849‑1

- Tamper protection better than with mechanical safety switches thanks to switches and actuators with individual coding

- LED status display including threshold indication for door displacement

- Degree of protection up to IP69 and resistance to cleaning products

- Larger switching displacement than with mechanical switches; offers better mounting tolerance and sagging tolerance of the protective door

|

3SE63

|

|

P_IC01_XX_00902

3SE64

|

RFID safety switch with tumbler

In addition to the features mentioned above for 3SE63, the RFID safety switch with tumbler has other advantages:

- 1 150 N locking force

- Suitable for protection of persons and/or processes (closed-circuit or open-circuit principle)

- Latching force adjustment 25 N/50 N by rotating the star handle through 180°

- Guard locking possible from three sides (three directions of actuation) by means of a star handle

- Assisted or escape release of guard locking

- Actuator can be used for door stop (using damper)

|

3SE64

|

|

G_IC03_XX_07385

3SU14

|

Commanding devices

SIRIUS ACT pushbuttons and indicator lights

- Using a special F adapter, EMERGENCY STOP devices according to ISO 13850 can be directly connected through the standard AS‑Interface or PROFIsafe with safety-related communication. This F adapter/fail-safe interface module is snapped from the rear onto the EMERGENCY STOP device, enabling the achievement of SIL 3 according to IEC 62061 or PL e according to ISO 13849‑1.

- Thanks to SIRIUS ACT with PROFINET, commanding and signaling devices can be connected directly via PROFINET to the controller and HMI devices – including with safety functions. Engineering and commissioning are simplified by the TIA Portal.

- EMERGENCY STOP devices for disconnecting plants in an emergency situation

- With positive latching function according to ISO 13850 and SIL 3 according to IEC 62061 or PL e according to ISO 13849‑1

- Various mushroom diameters (also illuminated), with lock, in plastic/metal, as individual or complete units, and in combination with 3SU1 enclosure or two-hand operation console. The 3SU1 enclosures are also optionally available with ASIsafe interface

|

3SU1

|

|

P_IC01_XX_00672

3SU1 with PROFINET

|

|

G_IC03_XX_29126 |

Cable-operated switches

- Control functions and EMERGENCY STOP always within reach

- More safety over long distances of up to 2 x 100 m length

- Easy release

- Fail-safe applications with SIRIUS Safety Integrated

- Status display directly on the switch

- Signal display for long distances in innovative LED technology with visibility over 50 m

- Cable-operated switches with latching according to ISO 13850 (EN 418) and full EMERGENCY STOP function with positive-opening contacts

- Quick and safe mounting using uniform mounting accessories

- Versions with 1 NO/2 NC with yellow lid

|

3SE7

|

|

G_IC03_XX_29090

3SE7

|

|

|

P_NSC0_XX_00379

3SE2924-3AA20

|

Safety foot switches

- Are used wherever manual operation is not possible

- With hood, IP65 metal enclosure

- With interlocking function according to ISO 13850, manual release by pushbutton switch

- With 2 NO + 2 NC, NO contacts close by momentary contact, positive-opening NC contacts with independent latching (safety function)

|

3SE2924-3AA20

|

|

P_IC01_XX_00903

8WD46

|

Electronically configurable 8WD46 signaling columns

- Compact and electronically modular design for flexible and versatile use

- Flexible segment configuration through individually adjustable colors (multicolor LED),

intensity and function (blinking, flashing, continuous or rotating light)

- Adjustable tones and volume

- Conventional signaling columns with configuration of the signaling columns via USB interface, with fast linking to the application through 8-pole M12 plug

- Signaling columns for IO‑Link configured via IO‑Link interface (IODD) and fast linking to the application through 4-pole M12 plug

|

8WD46

|

Connection methods

The 3SK safety relays are available with screw or spring-loaded terminals (push-in).

The 3TK2810 safety relays are available with screw or spring-loaded terminals.

3SK safety relays: Spring-loaded terminals (push-in) with TOP wiring

Push-in terminals are a form of spring-loaded terminals allowing fast wiring without tools for rigid conductors or conductors equipped with end sleeves.

As with other spring-loaded terminals, a screwdriver (with 3.0 x 0.5 mm blade) is required to disconnect the conductor. The same tool can also be used to wire finely stranded or stranded conductors with no end finishing.

The advantages of the push-in terminals are found, as with all spring-loaded terminals, in speed of assembly and disassembly and vibration-proof connection. There is no need for the checking and tightening required with screw terminals.

With the TOP wiring method, the wire inlet and terminals can be reached from the front. This helps to speed up the wiring process and eliminate wiring errors.

G_IC01_XX_00896

G_IC01_XX_00896

Video: SIRIUS spring-loaded connection - strong, flexible, safe, fast!