Overview

ENG_106084.XML

P_NC01_XX_01717

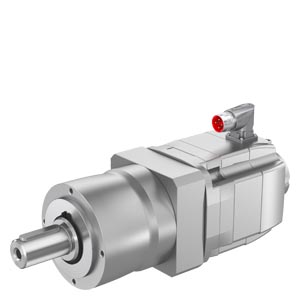

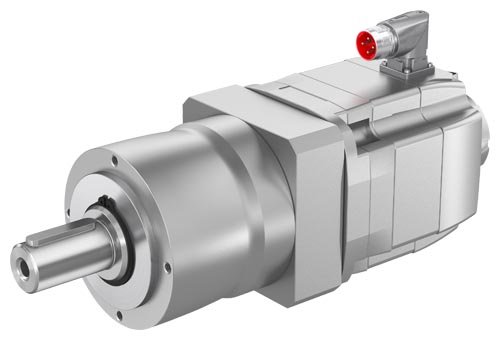

SIMOTICS S-1FK7 motor, with mounted NP planetary gearbox

SIMOTICS S-1FK7 motors can easily be combined with planetary gearboxes to form compact coaxial drive units. The gearboxes are flanged directly to the drive end of the motors.

When selecting the gearbox, ensure that its maximum permissible input speed is not exceeded by the maximum speed of the motor. In the case of high operating frequencies, allowance must be made for the factor f2 (see Configuration Manual, SIMOTICS S-1FK7 synchronous motors). The frictional losses of the gearbox must always be taken into account when engineering geared drives.

The gearboxes are only available in non-balanced design and with feather key.

Benefits

ENG_106085.XML

- High efficiency,

single-stage: > 97 %

- Minimum torsional backlash,

Single-stage: ≤ 10 arcmin

- Power transmission from the central sun wheel via planet wheels

- No shaft deflections in the planet wheel set due to symmetrical force distribution

- The gearboxes are connected to the motor shaft via an integrated clamping hub. A plain motor shaft end is necessary for this purpose. Shaft and flange accuracy tolerance N in accordance with DIN 42955 and vibration severity grade A in accordance with EN 60034-14 are sufficient. The motor flange is adapted by means of adapter plates.

- Output shaft of gearbox coaxial with the motor

- The gearboxes are suitable for all mounting positions.

- The gearboxes are enclosed (seal between gearbox and motor) and filled with grease in the factory. They are lubricated and sealed for their service life.

- Degree of protection of gearbox: IP64

- Small dimensions

- Low weight

Integration

ENG_106086.XML

SIMOTICS S-1FK7 motors can be supplied ex works (Siemens AG) in the shaft heights 28 to 100, complete with flange-mounted planetary gearbox.

The gearboxes assigned to the individual motors and gear ratios i available for these motor/gearbox combinations are listed in the subsequent selection table. The maximum permissible input speed of the gearbox (this is the same as the maximum motor speed) must be taken into account when a gearbox is selected.

The motor/gearbox combinations listed in the selection table are mainly intended for cycle operation S3-60 % (ON time ≤ 60 % and ≤ 20 min). Reduced maximum motor speeds and output torques apply for use in S1 continuous duty (ON time > 60 % or > 20 min). The gearbox temperature must not exceed 90 °C (194 °F).

Follow the instructions contained in the Configuration Manual for SIMOTICS S-1FK7 synchronous motors when assigning gearboxes to the motor.

Technical specifications

ENG_106087.xml

Continuous duty

Continuous duty is permissible at rated speed and rated torque. The gearbox temperature must not exceed 90 °C (194 °F).

|

Planetary gearbox NP

1-stage

|

Rated input speed

|

Rated output torque

|

|

Torsional backlash ≤ 10 arcmin

Type

|

n

G1

|

M

G2

at i = 5

|

M

G2 (T2N)

at i = 10

|

| |

r/min

|

Nm (lbf-ft)

|

Nm (lbf-ft)

|

|

NP 005

|

4000

|

6.5 (4.79)

|

–

|

|

NP 015

|

3700

|

21 (15.5)

|

19 (14.0)

|

|

NP 025

|

3400

|

50 (36.9)

|

45 (33.2)

|

|

NP 035

|

2600

|

125 (92.2)

|

110 (81.1)

|

|

NP 045

|

2000

|

350 (258)

|

200 (148)

|

Characteristic curves

ENG_841652.xml

Characteristics for the SIMOTICS motors are available via selectors through to the exact article number with the Siemens Product Configurator.

Access to the Siemens Product Configurator

The Siemens Product Configurator can be accessed without having to register or log in:

www.siemens.com/spc

→ SIMOTICS S-1FK7 in the SPC

Dimensional drawings

ENG_841651.xml

Dimensional drawings for the SIMOTICS motors are available via selectors through to the exact article number with the Siemens Product Configurator.

Access to the Siemens Product Configurator

The Siemens Product Configurator can be accessed without having to register or log in:

www.siemens.com/spc

→ SIMOTICS S-1FK7 in the SPC

Assets

Taking the tour will redirect you to our new platform. You can always come back either by hitting back button on the browser or by opening the URL again.