ENG_34983.XML

Systems Engineering Plant Chemnitz (WKC) - Electrical equipment for machines and plants

The Siemens Systems Engineering Plant Chemnitz (WKC) is the European market leader in control cabinet construction for machine tools and manufactures equipment for numerous segments the machine and plant construction industry, as well as for project business in the logistics and automotive sectors.

P_NC01_XX_01729

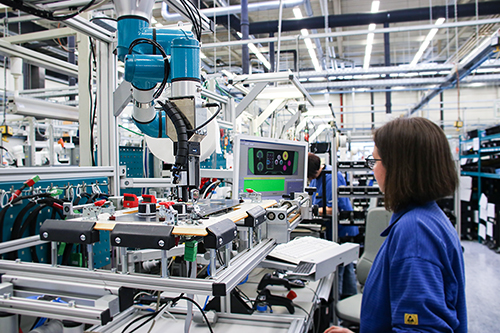

WKC - Control cabinet wiring

Scope of services offered

The WKC offers a complete portfolio of services for development and production: From concept support and hardware engineering, construction including complete material procurement to testing, advance commissioning support and worldwide inbound delivery. Each customer decides individually what extent of these services the WKC is to provide.

P_NC01_XX_01732

WKC - Engineering - SSB

Competence center for standardization and air conditioning

The WKC is also competence center for the air conditioning of switchgear, has its own test laboratory, and is a certified UL Panels shop. Siemens WKC therefore is happy to support you with advice on design in accordance with standards and concepts for your drive systems, control, operation and safety. In addition, our engineers configure for you in EPLAN and other CAD systems, execute Design-To-Cost projects, and adapt your documents where necessary to UL or new automation and digitalization technologies.

P_NC01_XX_01730

WKC - Test laboratory - Heat measurement

Individual support and maximum flexibility

Our technical consultants for complete equipment support customers and sales departments in the various regions. Our customers are supported by job centers and permanently assigned manufacturing teams. As a customer, you will benefit from individual logistics models, flexible production capacities and production areas, change management in all process phases, as well as maximum flexibility for your orders. Distance is no problem: For coordination with our customers, we use various digital communication and business applications with user-friendly and powerful functions for screensharing, videoconferencing, file transfer, as we all options for a customer acceptance via webcam (mobile circuit meeting room).

P_NC01_XX_01728

WKC - Automated testing SICAT

Your advantages

We offer complete services from a single source with Siemens quality and stability, extensive specialist support, and flexible resources. We will be glad to accompany you into international markets as well. With us you have a strong partner at your side - from the design stage to final delivery. Whether for series or individual units, Siemens WKC works together with you to implement your projects according to your requirements.

Overview of the portfolio of services

Order coordination

- Project manager with permanent customer assignment

- Complete material purchasing

- Change management in all process phases

Manufacturing

- Creation of a digital twin

- CNC processing of enclosure parts and mounting plates

- In-house painting

- Auto-routing of the wiring

- Automated prefabrication of cables

- Production teams with permanent customer assignment

- Batch or flow production

Automated test (standard)

- Current path test

- Function of switching, operating and signaling devices

- Observance of protective measures and safety

Optional test services / pre-commissioning

- Error-free function of the programmable controllers / I/O devices

- Parameterization and checking of bus systems

- First commissioning of Siemens NC and PLC

- Installation of customer software

P_NC01_XX_01733

WKC - Collaborative robotics

Additional services for different project phases

Our portfolio is supplemented by a host of additional services for many different project phases.

Planning

- Evaluation of requirement specifications, requirements

- Advice regarding standard applications and certifications (conformity)

- Advice regarding EMC, air conditioning, and electrical safety

- Design-To-Cost analyses

- Special rated conditions

Implementation/realization

- Creation of an electrical design in various CAE systems

- Creation of an air conditioning design through calculation and simulation

- CAE revision of production documents

Validation/certification

- International standard and certification know-how, e.g.: IEC 60204-1, IEC 61439, UL or cULus

- Checking of air conditioning / EMC designs in own Siemens laboratory or at customer premises

- Execution of EMC precompliance measurements in own laboratory or at your plant location

P_NC01_XX_01731

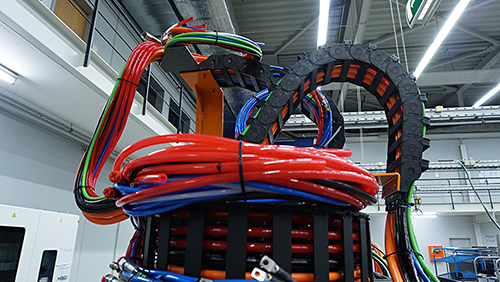

WKC - Additional service - Festoon cable system